Giving waste plastics a new lease of life

Dr Helen Liang explains how support from the University of Bath helped launch her start-up to tackle the hidden plastics problem in scientific research.

Plastic pollution is a well-known environmental problem. The very thing that makes plastic so useful – its toughness and resistance to chemicals – is the property that makes it so polluting, with most plastics taking centuries to break down.

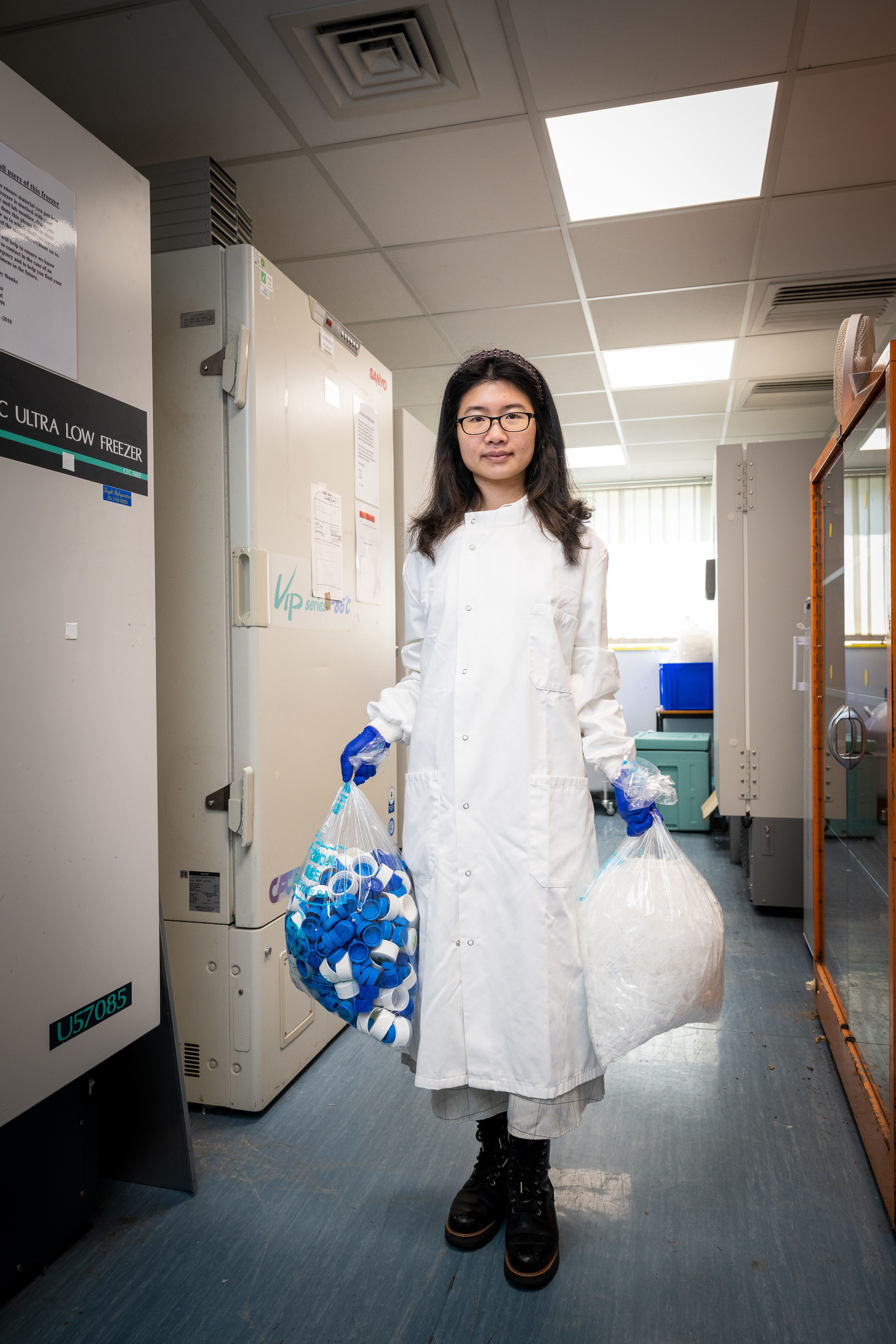

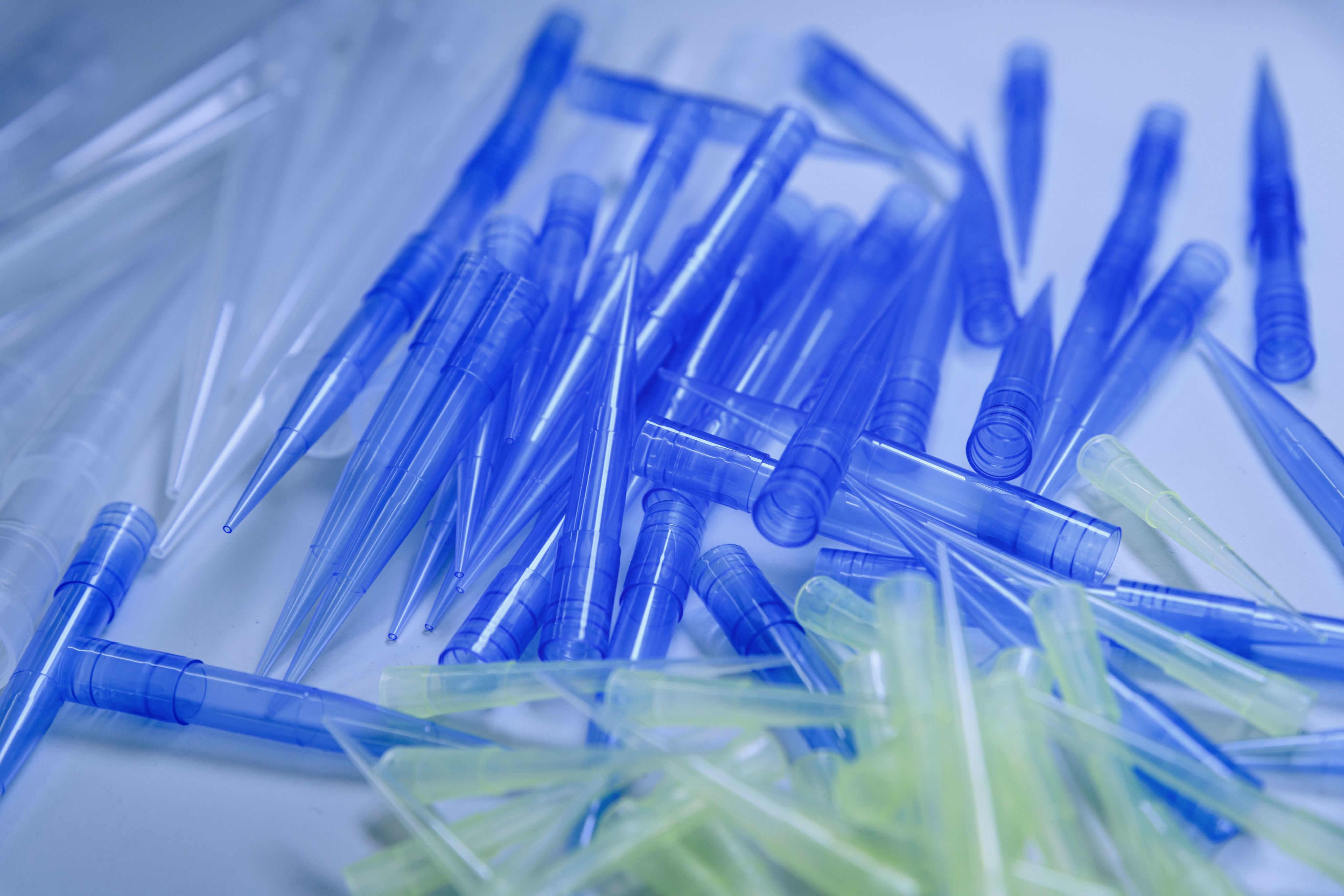

Whilst most of us recycle our drinks bottles and food packaging, and try to reduce how much plastic we throw away, there are mountains of single-use plastic waste being produced by hospitals, universities and science labs every day that most of us have never even thought about.

To avoid cross-contamination that could skew experimental results, researchers throw away huge numbers of pipette tips, petri dishes, test tubes and bottles after only one use. Hospitals also routinely use single-use plastic items to ensure they are clean and sterile, avoiding cross-contamination of samples and reducing potential spread of infection between patients.

Each year, it’s estimated that research and healthcare laboratories across the UK produce over 150,000 tonnes of single-use plastic waste, the equivalent mass of an aircraft carrier. Most of this ends up being incinerated, which can produce polluting gases, or in landfill, where it stays for hundreds of years.

Ironically, many of the scientists trying to solve environmental problems through research are currently adding to the problem through plastic pollution.

When Dr Helen Liang was studying for her PhD at the University of Bath, the sheer quantity of waste upset her so much that she decided to set up her own company, called LabCycle, to tackle the problem.

The main obstacle for recycling lab waste is that much of it is contaminated with biological or chemical materials, so waste disposal typically involves sterilising it with high temperature and pressure (in a machine called an autoclave) before disposing it via landfill or incineration.

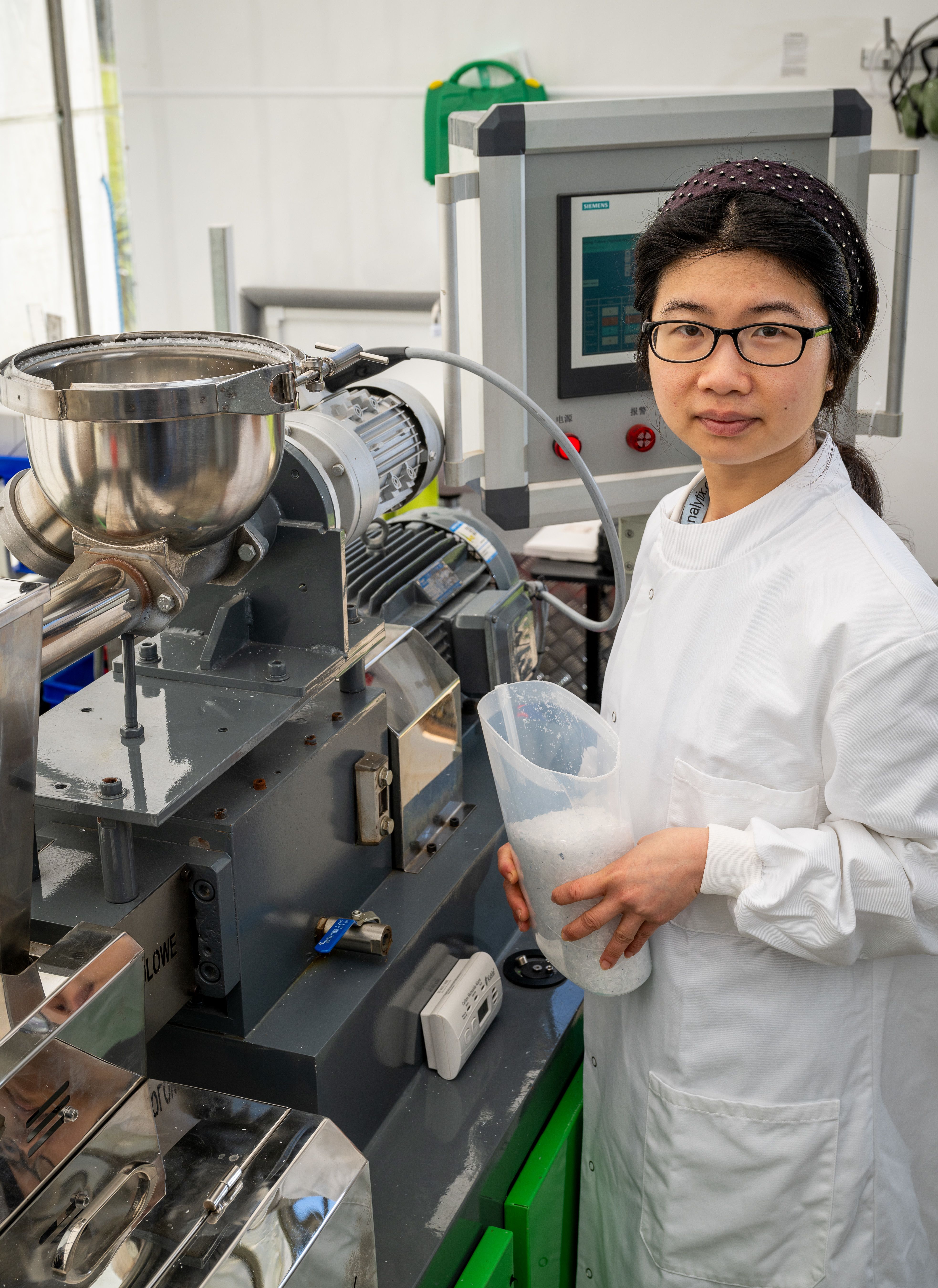

LabCycle has developed a system to sort different plastic types and decontaminate them to allow them to be safely recycled into high-quality recycled plastic pellets the size of rice grains, which are sent to LabCycle’s manufacturing partner to turn into new lab equipment.

Their unique recycling process doesn’t require waste to be autoclaved beforehand, meaning less heat energy is needed. Water usage is also minimised through recycling, further reducing the environmental impact.

Helen’s vision is to recycle at least 40% (around 60,000 tonnes) of single-use lab plastic waste per year and turn it back into new lab equipment, creating a circular economy and making a huge impact on the amount of plastic waste thrown away by the scientific and biomedical sectors.

“Our ultimate goal at LabCycle is to help the research and healthcare sectors to be more sustainable and significantly reduce their single-use plastic consumable waste, decontaminating it and recycling it to make new lab items, thus creating a circular economy.”

Helen's entrepreneurial journey

Helen’s entrepreneurial journey began at the end of 2019, when she met LabCycle co-founders from the University of Surrey at a three-day start-up programme run by SETsquared, the award-winning global business incubator and accelerator partnership between the Universities of Bath, Bristol, Cardiff, Exeter, Southampton and Surrey.

Helen became a Marie Curie Entrepreneurship Champion during her PhD, organising workshops and inviting researchers at the University who had successfully commercialised their research or started their own businesses to give talks and share their experiences.

In the final year of her PhD, she entered her business idea for LabCycle into Enterprise Bath’s annual Dragons’ Den pitching competition, where she was awarded funding that enabled her to do further market research. It was then she realised the huge market demand for this service and the potential commercial opportunity.

Helen says: “This was a real turning point in my journey, as for the first time I was able to talk to experienced businesspeople, get their validation of the project as well as being awarded funding to help develop a fully-fledged business model.”

Having had her idea validated by her market research, Helen forged ahead with her plans for LabCycle and took advantage of the numerous opportunities available at the University to nurture enterprise activities.

SETsquared’s Student Enterprise Programme gives students and graduates opportunities to gain hands-on entrepreneurial and business experience, as well as mentoring support by enterprise experts to develop a successful business model.

Helen was paired with business mentor Pete Keevil, Entrepreneur in Residence at the University of Bath Innovation Centre.

LabCycle also got support in developing their business model from Professor Matthew Davidson, Director of the University of Bath’s Centre for Doctoral Training in Sustainable Chemical Technologies - where Helen did her PhD training – who became an advisor for the company.

Professor Davidson, who is also Director of the University’s Institute for Sustainability and Executive Director of iCAST, said: “Helen spotted an opportunity to make a huge commercial sector more sustainable and has had the confidence and tenacity to make her recycling vision a reality.

“Seeing entrepreneurial PhD researchers like Helen really make the most of the opportunities open to them is one of the real pleasures of my role. While we can provide them with the necessary support and some advice, the vision and the drive comes from the entrepreneurs themselves.

“Helen has done a fantastic job so far and I look forward to contributing a small part to the success of Labcycle as it develops.”

SETsquared also helped Helen along her business journey by providing networking opportunities, masterclasses, and support with grant writing, which has been very fruitful.

At the end of 2020, Helen secured funding from the University of Bath’s Alumni Innovation Award, which gives winners financial support for one year to set up and develop their business.

The co-founding team officially registered the company as LabCycle Ltd in January 2021.

Helen says: “It was challenging to manage my final year PhD and a start-up company at the same time, but I learned so much and really enjoyed it.

“The spirit and passion for entrepreneurship is so strong at the University of Bath, which was one of the key factors that inspired me to start my own business.”

LabCycle has since been awarded over half a million pounds worth of investments from grants and private investors including the Santander University Fund and the Royal Academy of Engineering, as well as Government funding from UKRI and SBRI grants.

Dr Helen Liang

Dr Helen Liang

A big challenge to get the technology off the ground was to ensure the process complied with regulations and standards such as ISO 12771 Standards for Plastic Laboratory Ware.

Helen says: “Each time plastic is recycled, it loses a bit of quality. The heating processes during mechanical recycling shortens the polymer chains, which degrades the quality.

“Currently polypropylene can be recycled four or five times before it can no longer be used for labware.

“However, since most of the plastic waste generated by labs is from virgin plastic, we can blend the recycled plastic waste with a large proportion of waste from virgin plastics in each batch, extending the potential lifecycle of the waste 10-20 times depending on the plastic type.”

LabCycle partnered up with the Innovation Centre for Applied Sustainable Technologies (iCAST), a research and development centre that uses expertise from the Universities of Bath and Oxford to support businesses in the sustainable technology sector.

Find out more about iCAST

Using the waste collected from labs at the University of Bath for their pilot to recycle single-use plastic, the teams worked on characterising and evaluating the plastic resins from decontaminated lab waste, and proposing an optimal strategy to use these recycled plastics for manufacturing ISO-compliant lab consumables.

Following their successful pilot project recycling single-use plastic waste from three labs at the University of Bath in 2022, the team started work to roll out the service commercially, attracting nearly £100,000 funding from SBRI Healthcare to work with NHS Blood and Transplant to contribute to delivering a Net Zero NHS.

In summer 2023, with support from the Faculty of Science, iCAST and the Campus Infrastructure team at the University of Bath, LabCycle set up the UK’s first pilot plant for recycling plastic lab waste, using a converted greenhouse on the University’s Claverton Down campus.

In the past year, LabCycle has managed to divert more than one tonne of single-use plastic from landfills or incineration from five facilities. This is the equivalent of more than three tonnes of CO2 reduction.

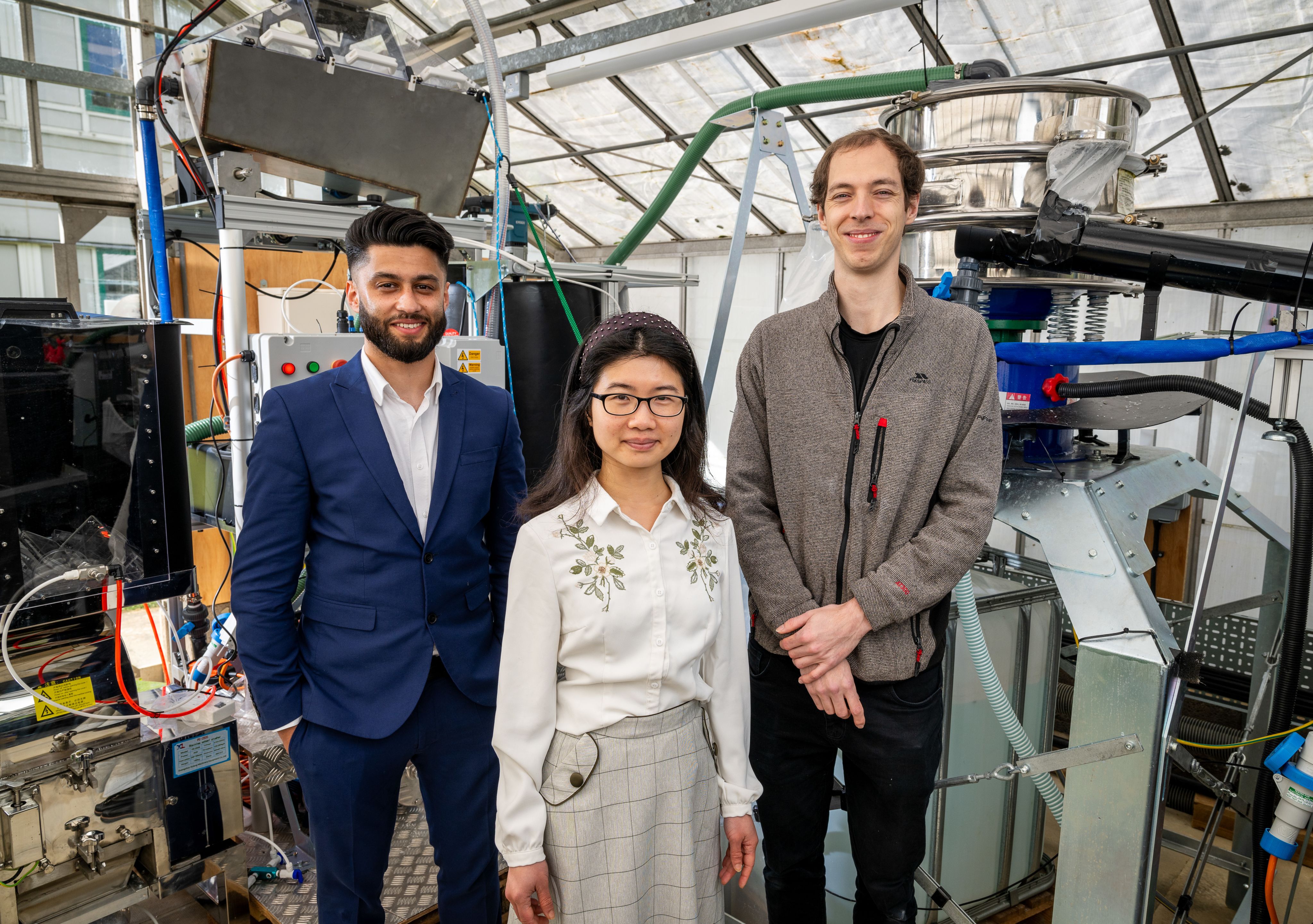

L-R: CEO Colin Francis, CTO Helen Liang and Engineer Gareth Barnaby.

L-R: CEO Colin Francis, CTO Helen Liang and Engineer Gareth Barnaby.

The company is now looking to scale up the technology and partner with more organisations to roll out their waste processing service in multiple locations across the UK.

They are now securing protection of the associated intellectual property through a trademark and patent process.

They have planned to integrate the recycling plant into a shipping container so that labs and hospitals can recycle their waste streams near the point of collection, reducing the carbon footprint versus transporting waste to a central hub.

The recycled labware will be sold back to the labs to further reduce their environmental footprints. The eventual aim is for the service to be around the same price as current waste disposal systems.

Following a BBC News article in November 2023, Helen has been contacted by more than 85 companies including several major multinationals expressing a strong interest in exploring collaboration opportunities.

The company has also been selected as finalist for two categories in the South West UKStartUp Awards.

Helen says: “The enthusiasm of users in the lab has been overwhelming – researchers in the healthcare sector are really keen to do something different and recycle their plastic waste.

“It’s really motivating to know we’re doing something positive to make a difference and make scientific research more sustainable.”

Helen speaks to Professor Jonathan Knight, Vice-President (Enterprise), about how the University's support helped her develop LabCycle, the first company on the market to create a circular economy for single-use plastic waste from Safety Level 1&2 labs.

Find out more about our Innovation with Impact

Learn more about the Innovation Centre for Applied Sustainable Technologies

The Innovation Centre for Applied Sustainable Technologies (iCAST) is a unique collaboration that brings together experts in industry and academia to translate innovation in green, sustainable technologies into commercial application.

Transforming Laundry: From Promise to Global Impact

Navjot Sawhney, founder of the Washing Machine Project, explains how the Alumni Innovation Award from the University of Bath supported his mission to liberate people around the world from the toil of hand-washing clothing.