Developing a sustainable alternative to palm oil

How a yeast fed on waste could take a seat at the dinner table – and curb deforestation

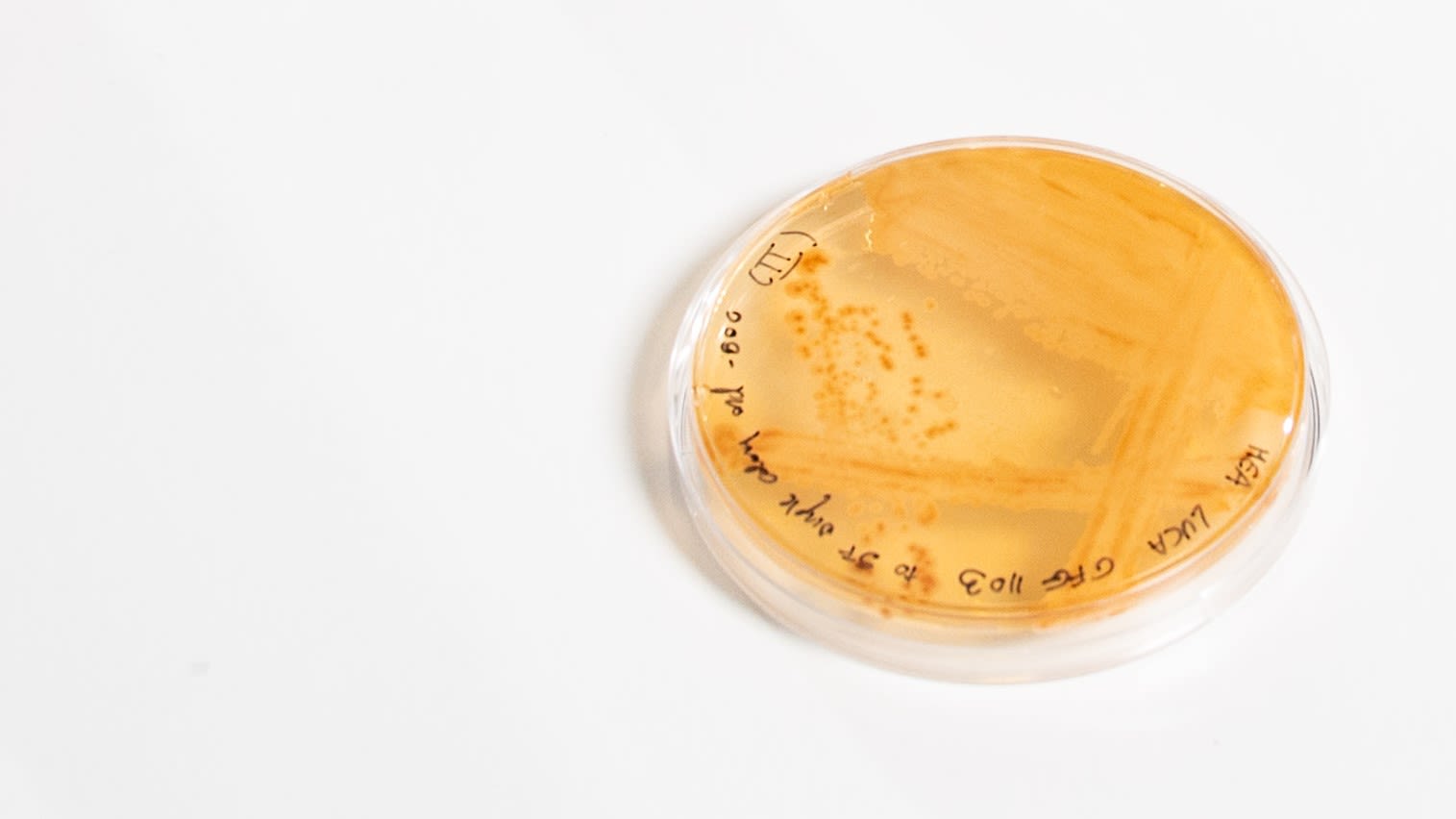

It may look unremarkable, but the yeast in this petri dish is different. Despite the care spent in its development, it’s not fussy – it can be fed on common waste products including straw, waste paper and sawdust.

A unique strain of Metschnikowia pulcherrima – or Mp for short – it is the result of years of effort, trial and error, and even a form of lab-based, accelerated evolution.

Most importantly, it could become a crucial tool in combating some of the most important challenges we face today: climate change caused by deforestation, and food security.

How? The oil it produces has the potential to replace palm oil.

The problem with palm oil

Palm oil is almost everywhere.

Almost tasteless yet with a smooth, silky quality, and solid at room temperature with a high melting point, it’s an ingredient ideal for many products. It gives cookies their creamy texture, keeps spreads solid, and even holds the colour in lipstick. It’s been estimated that palm oil or its derivatives are in half of the packaged products in supermarkets.

And while you might be able to look at the wrapper of a chocolate bar and find palm oil listed among its ingredients, you just as likely not to, even when it is. This is because the oil is processed and fractionated into components before being processed again into different ingredients, with names including Palmitate, Palmolein, Glycerin, Stearate and Stearitic Acid. There are easily over 100 names for palm oil-derived ingredients.

But where does it come from?

Oil palm is a tropical plant that thrives in the sunlit, humid and rainy latitudes close to equator – in countries in South America, Africa and Southeast Asia

From a certain standpoint, oil palm in a wonder crop. It yields more oil per hectare than any other plant – almost four times more than sunflowers, its closest competitor. It is cheap to grow and harvest, and it can be used in a diverse range of products – chiefly foods, cosmetics and cleaning detergents.

Production of palm oil has risen rapidly over the past 50 years: the 71 million tonnes made globally in 2018 was 35 times more than in 1970. And while yields (the amount of oil produced from a given area of land) have risen, a key driver of the explosion in production is large-scale deforestation that harms natural habitats and forest carbon-sinks, creates water and air pollution and generates huge emissions.

Since 1980, the amount of land used to grow oil palm has more than quadrupled – rising from 4 million to 19 million hectares in 2018. Today, Malaysia and Indonesia are together the world’s palm oil factories, accounting for 84% of all production. Between 2001 and 2016, over 2 million hectares of Indonesia’s forest was turned over to oil palm growing.

Despite the rate of deforestation for oil palm in those countries slowing in recent years, there is a clear need to cut it further.

Competing with a wonder crop

This is where the work of a team led by Chris Chuck, a Professor of Bioprocess Engineering in the University of Bath’s Department of Chemical Engineering, comes in.

“What we need is to slow growth in traditional agricultural production, which leads to deforestation, while helping producing nations move toward more sustainable practices,” he says. “We need to protect forests that are still there, we need to curb growth and that’s where experimental food technologies, like the one we’ve developed, can come into play.”

So, how can you slow deforestation and compete with a wonder crop?

“Our aim is to replace tropical oils that cause deforestation with a sustainable alternative,” he says. “With palm oil being the most consumed edible oil, we have done just that, with a yeast that makes an oil that performs just like palm oil.”

Prof Chuck has been working to understand the behaviour and potential of many oil-producing organisms, to find one that offers the chemical and commercial flexibility, robustness and high yields that an alternative to oil palm needs.

“Organisms that produce oil on a scale that could compete with palm oil don’t exist in nature. We have had to develop them, learn how they function, and develop highly optimised ways of growing them at scale, so we can offer food producers, retailers and consumers something that’s better and more sustainable that the real thing,” he says.

Alongside that deep understanding, he and his team, have amassed a wealth of expertise on the needs of industry players, in order to understand what's required to replace palm oil at industrial scale. He says: “A lot of researchers will only work in one area, but we realised that we had to be much broader in our outlook. We are a very multi-disciplinary team with biologists, chemists, mechanical engineers, chemical engineers, and food scientists all working together towards the solution.

“To be able to commercialise, we have to be able to anticipate and answer a lot of questions that industry will ask. Knowing the cost of each part of our process, the sustainability impacts, and exactly what the products are, what’s in them, and how they behave is critical if we’re to offer the food industry something useful.”

Early in the development process, the team concluded that the feedstock used to grow the yeast must itself be renewable or drawn from unused waste products – otherwise making it could simply create new sustainability challenges. This is why their strain of Mp yeast has been developed with the capability of being cultured on low-cost feedstocks, including agricultural stover (the leftover leaves and stalks of field crops), waste food and even grass.

Harnessing evolution

How has this development taken place? Many bioengineering techniques were used throughout the process, a key one being Adaptive Laboratory Evolution (ALE).

By subjecting the original Mp yeast to iterative rounds selection based on it desirable attributes and amplification of those attributes, the team was able to employ a form of natural selection to create strain optimal for their needs.

Bath’s campus community provides the ideal setting for cross-disciplinary work like this. Prof Chuck teamed up with Dr Daniel Henk, a member of Bath’s Milner Centre for Evolution, to develop the strain of Mp yeast.

Dr Henk says: “Essentially we grew the yeast in a variety of conditions and with selective pressures that challenged its ability to grow. Over time you end up with a population that is more adapted to grow in spite of a selective pressure, and then you can start again and apply another. The key things we could select for were to either grow quickly, or to survive, in conditions from extreme temperatures to growing on a medium like the waste feedstocks. We worked through hundreds of generations of yeast over many months to arrive at this one.

“The project has widened our understanding of how yeasts can adapt and how they react to different organisms. A single yeast can’t necessarily be evolved to do all of the different jobs, but what’s exciting to us is that there are a lot of other yeasts which could be developed in a similar way to provide different, but equally valuable solutions to other problems that we face.”

The qualities the team selected for were a capability of the yeast cells to produce high quantities of oil and be grown in bioreactors (a key element of scalability); an ability to be grown at high density, with hardiness and resistance to bacterial invasion, and an ability to be fed a wide range of feedstocks – such as sustainable sugars based on waste products.

The Milner Centre for Evolution

The Milner Centre for Evolution

Time to harvest

Having grown the yeast, the team refined their process and subjected the resulting oil to a battery of tests to ensure it shares palm oil’s qualities for use in foods and could become a like-for-like replacement.

The next stage in production is harvesting the oil from the yeast cells. This takes in several steps: preparing feedstock, feeding the yeast, harvesting it, then extracting the oil.

Instead of growing a yeast, then harvesting it all in a batch process, the team grows it to an extremely high concentration – more than you would normally see in real-world or lab conditions – then harvests a proportion of the cells, before feeding the remainder with more nutrients and continuing the process over months.

At the point of harvesting, the yeast cells are full of oil. The final stage is to extract the oil through a special process that combines pressure with a dissolving and grinding action to separate the oil completely from the yeast. This is a high-energy, fast process – but also expensive. Because of this, the team has developed lower energy methods for extraction as well as exploring valorising all of the products that the yeast produces.

“By using the rest of the cell biomass for other products, for example in creating a substitute for soya protein,” says Prof Chuck. “They could present a double benefit of being simple to produce, while offering a higher yield. So, the critical element of this technique is making the feedstock as cheap as possible.”

Giving palm oil a run for its money

The team is currently working at the pilot scale and producing kilograms of oil every week. They are actively ramping up the process to the industrial scale in collaboration with the Clean Food Group.

When they move into the next phase of work, the goal is to move production into the tonnes-per-week range.

Prof Chuck says his vision is that in five years, we could see 500,000-litre bioreactors, similar in scale to tanks used by major breweries, being used to produce the yeast and unlock the cost competitiveness of the process, and finally give palm oil a run for its money.

Big business is certainly listening.

After attracting media attention over several years for their work, in 2016 Chuck’s team achieved a surprising mention – in the Netflix show Grace and Frankie, which stars Jane Fonda and Lily Tomlin.

Just watching @Netflix's @GraceandFrankie & came across this scene. Those scientists are my old group, @ChuckGroup! pic.twitter.com/lOD9D2MpoY

— Rhod Jenkins (@rhodrij) May 17, 2016

“This isn’t niche work – the problems with palm oil are really well known, and lots of research has been done by some of the world’s biggest companies to combat the issue,” Prof Chuck says. “The barrier has always been with price and performance – and that’s the rub. We know we have a product that performs – we just need to prove it at greater scale.

“The interest in the work we’re doing, and other researchers working in similar ways, is something producers are incredibly interested in. They want to fix the issue, in a way that is acceptable for their business – and it’s clear that a sustainable alternative to palm oil would be a huge marketing opportunity.

“A lot of people would be happy to take a little bit of a hit to buy a more sustainable product. We’re not as price-sensitive as you might imagine – but ultimately you need to get somewhere close to competing on price to have a chance of replacing palm oil.”

He predicts that in the next two to five years, we will see a massive increase in the number of precision fermentation products (of proteins and other ingredients from from cell culture). This is not a battle that one competitor will win, he stresses: “There are a number of start-ups looking at addressing issues associated with our food systems, and we will need a number of companies to come forward with credible alternative products to make a difference, and soon.”

The team's current scale-up reactor

The team's current scale-up reactor

The scale Prof Chuck thinks yeast-based palm oil could be produced at in future (zinkevych / Adobe Stock)

The scale Prof Chuck thinks yeast-based palm oil could be produced at in future (zinkevych / Adobe Stock)

Benefits beyond curbing deforestation

The opportunity of lab-grown ingredients to solve other issues, Prof Chuck says, is a further side benefit: “You consider the world now, and you can see the volatility of the sunflower oil market following the conflict in Ukraine. Then Indonesia banned exports of palm oil after prices for edible oils rose sharply. The advantages of a stable supply in the face of a volatile market are there for all to see.

“If the UK could now reduce its reliance on imports of certain foods and ingredients it will help us to weather storms like this in the future, and especially climate change. Put simply, techniques like ours could change what can be grown where. And it’s possible that the way we look at cost could become more based in stability of supply than outright cost.”

A further less-discussed advantage offered by alternative oils is the that they will give food producers the scope to be creative.

Prof Chuck says: “We have the chance to create genuinely new types of food – not just replacements for things we already know, but things that are totally new - tastes, textures, smells, and foods that are healthier, and which you know precisely what has gone into them.

“Beyond palm oil, a lot of other tropical oils have just as big an impact, and there is massive scope to produce other alternatives, and other new foods.”

“The technology we have developed is being scaled, we are looking forward to seeing our products on shelves soon, and the possibilities with this platform are practically endless. Without sounding too fanciful, the main question we are asking ourselves now is – what can we create next?”

Whatever it is, its role in saving vital habits and forest carbon sinks and reducing emissions could prove vital.

See research papers for this project:

The viability and desirability of replacing palm oil Sophie Parsons, Sofia Raikova & Christopher J. Chuck (2020) Nature Sustainability DOI: https://doi.org/10.1038/s41893-020-0487-8

Semi-continuous pilot-scale microbial oil production with Metschnikowia pulcherrima on starch hydrolysate Felix Abeln, Robert H. Hicks, Hadiza Auta, Mauro Moreno-Beltrán, Luca Longanesi, Daniel A. Henk & Christopher J. Chuck (2020) BMC Biotechnology for Biofuels DOI: https://doi.org/10.1186/s13068-020-01756-2

The additive free microwave hydrolysis of lignocellulosic biomass for fermentation to high value products Jiajun Fan. Fabio Santomauro. Vitaliy L. Budarin, Fraeya Whiffin, Felix Abeln, Tanakorn Chantasuban, Deborah Gore-Lloyd, Daniel Henk, Roderick J. Scott, James Clark, Christopher J. Chuck (2018) Journal of Cleaner Production; DOI: https://doi.org/10.1016/j.jclepro.2018.07.088

Low-cost lipid production by an oleaginous yeast cultured in non-sterile conditions using model waste resources Fabio Santamauro, Fraeya M Whiffin, Roderick J. Scott & Christopher J. Chuck (2014) BMC Biotechnology for Biofuels; DOI: https://doi.org/10.1186/1754-6834-7-34

Images by Laurie Lapworth / University of Bath unless credited

Video by Simon Wharf / University of Bath unless credited

Current and former members of the sustainable palm oil project team include:

- Dr Felix Abeln

- Montazar Al-Nijir

- Dr Hadiza Auta

- Dr Florent Bouxin

- Dr Vitaliy Budarin

- Dr Alice Fan

- Dr Debs Gore Lloyd

- Dr Rob Hicks

- Dr Luca Longanesi

- Dr Mauro Moreno

- Scott Nielsen

- Harriet Parkinson

- Dr Sophie Parsons

- Dr Javier Remon

- Dr Fabio Santomauro

- Dr Jia Wu